In the intricate world of electrical systems, the efficiency and accuracy of current measurements stand as pivotal components for ensuring safety, reliability, and performance. Amidst the plethora of devices and technologies designed for this task, the Direct Current (DC) Shunt emerges as a fundamental, yet profoundly influential component. This pillar post aims to dissect and explore the myriad facets of DC Shunts, unraveling their essential role and far-reaching impact across various sectors. By diving deep into the mechanics of DC Shunts, comparing them with other current measuring devices, and highlighting their practical applications in industries ranging from industrial control systems to automotive and transportation, this comprehensive guide will illuminate the significance of DC Shunts. Whether you’re an engineer, a technician, or simply an enthusiast of electrical technology, understanding the function, application, and importance of DC Shunts is crucial for grasping the broader narrative of electrical system efficiency and innovation.

Understanding the Function of a DC Shunt

What is a DC Shunt?

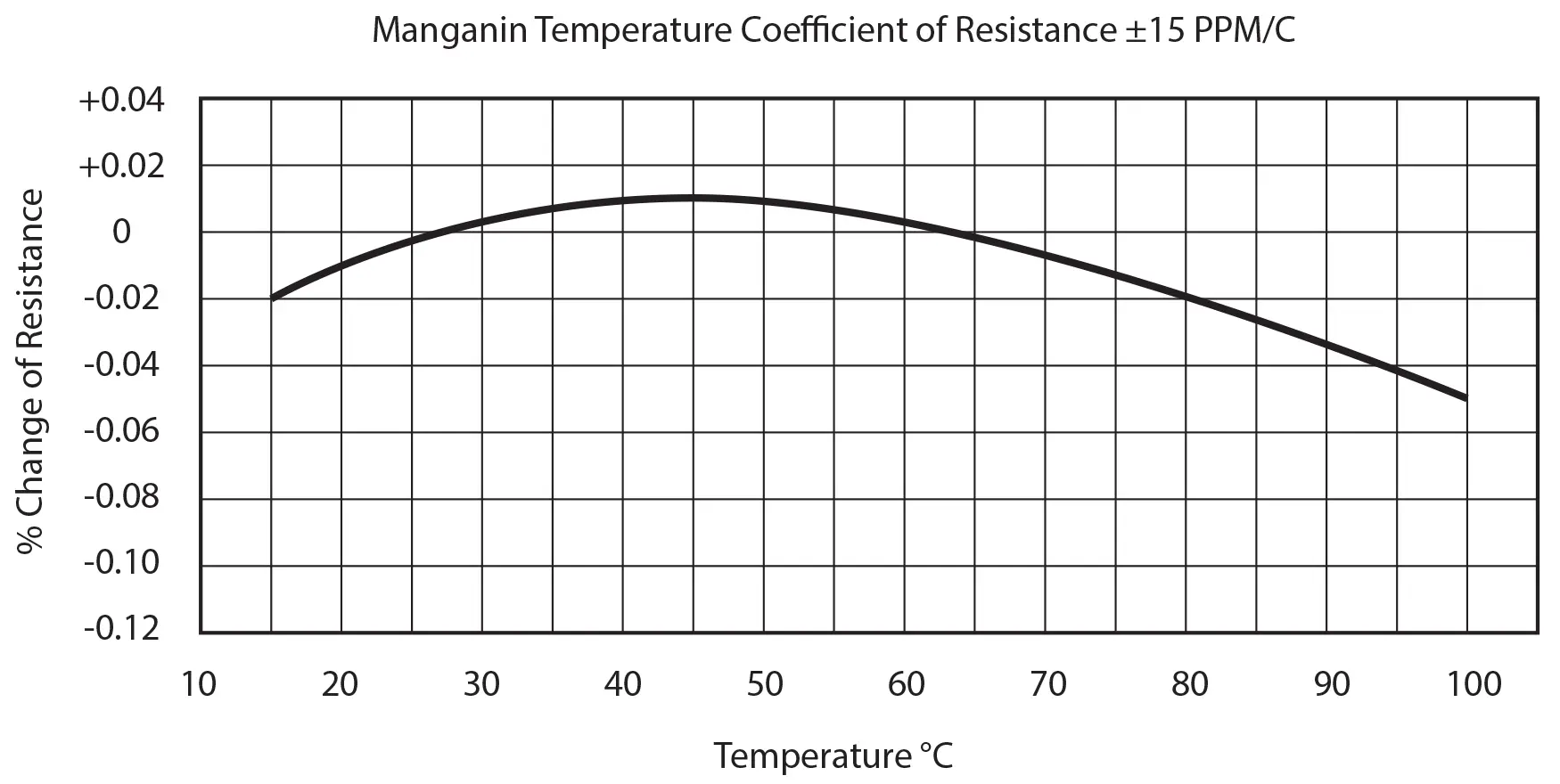

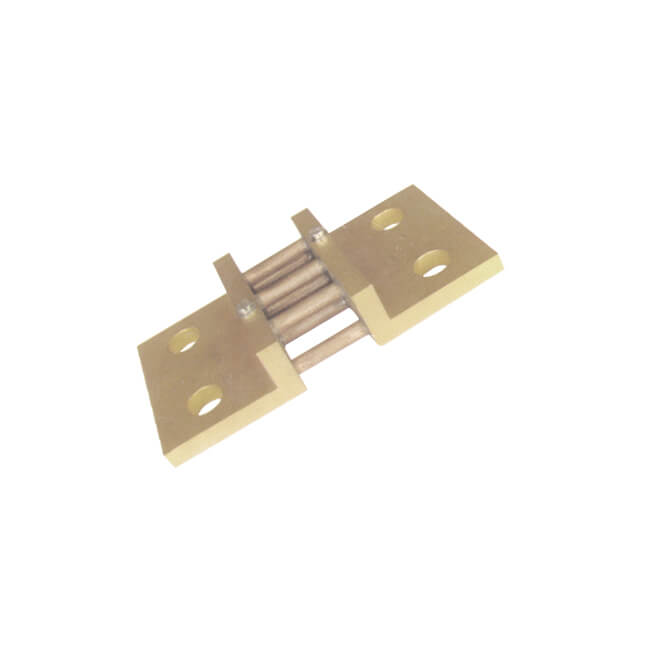

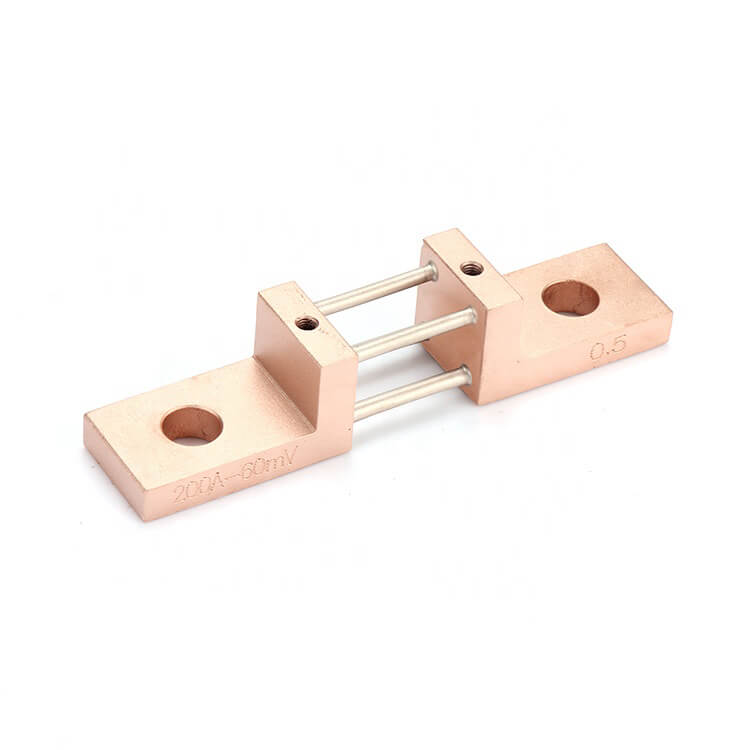

A Direct Current (DC) Shunt is a precision resistor that converts current into a proportional voltage, serving as a cornerstone in the measurement of electrical current in circuits. Constructed from materials with a known and stable resistance, DC Shunts are integrated into circuits with the intent of having a minimal impact on the overall current flow, while still allowing for accurate measurement.

Core Function of a DC Shunt

The core function of a DC Shunt revolves around its ability to facilitate the precise measurement of current without significantly altering the circuit’s performance. By creating a parallel connection within the circuit, it ensures that a portion of the current is diverted through the shunt. The voltage drop across the shunt is then measured and, given the known resistance, allows for the calculation of the current flowing through the circuit based on Ohm’s law (V=IR).

Importance of Accurate Current Measurement

Accurate current measurement is crucial in electrical systems for several reasons:

Safety: Prevents overcurrent that can lead to overheating and potential failures.

Efficiency: Enables the optimization of electrical systems for better energy consumption.

Reliability: Ensures devices operate within their designed electrical parameters, promoting longevity.

Practical Applications

DC Shunts are ubiquitous in applications where precision current measurement is essential. From monitoring battery systems to assessing the performance of photovoltaic solar panels, their role is indispensable in translating raw current measurements into actionable data.

Comparing DC Shunts with Other Current Measuring Devices

In the realm of electrical engineering, understanding the flow of current within a system is paramount. While DC Shunts stand as a traditional method for this purpose, advancements in technology have introduced a variety of devices designed for current measurement. This section compares DC Shunts with other prominent technologies to highlight their respective advantages and practical use cases.

DC Shunts

Pros:

High Accuracy: Known for their precision, especially in high-current applications.

Simple Implementation: Easy to integrate into existing circuits without the need for complex setup.

Cost-Effective: Generally more affordable than sophisticated electronic sensors.

Cons:

Physical Space: Requires physical space within the circuit, which might not be ideal for compact designs.

Heat Generation: Can generate heat under high current, necessitating careful consideration in design to dissipate it.

Hall Sensors

Pros:

Isolation: Offers electrical isolation between the measuring circuit and the current being measured, enhancing safety.

Compactness: A smaller physical footprint allows integration into tighter spaces.

Versatility: Capable of measuring both AC and DC currents.

Cons:

Cost: Typically more expensive than DC Shunts, especially for high-accuracy models.

Sensitivity to External Factors: This can be affected by external magnetic fields, potentially compromising accuracy.

Other Current Measuring Devices:

Other devices, such as current transformers (for AC) and Rogowski coils, provide alternative means of current measurement. These devices are often used for specific applications where DC Shunts or Hall Sensors may not be suitable, offering benefits like higher measurement ranges and flexible form factors.

Practical Applications of DC Shunts in Various Industries

DC Shunts’ versatility shines across multiple sectors, demonstrating their enduring relevance in modern electrical engineering.

Industrial Control Systems: Used for monitoring and controlling machinery, ensuring operational safety and efficiency.

Power Generation: Essential in managing the flow of current in power stations and renewable energy systems, aiding in grid stability and distribution accuracy.

Electrical Circuits: Fundamental for testing and development, providing precise measurement for circuit optimization.

Automotive and Transportation: Key in electric vehicles (EVs) and charging stations, monitoring battery and charging currents for performance and safety.

Other Industries: From aerospace to telecommunications, DC Shunts contribute to the reliability and accuracy of electrical systems worldwide.

Conclusion

The exploration of DC Shunts within electrical systems reveals a component that is as fundamental as it is critical. Through our journey from understanding their basic function to comparing them with modern measuring devices and highlighting their indispensable applications across various industries, the enduring significance of DC Shunts becomes undeniably clear. Despite the advent of newer technologies, the simplicity, accuracy, and cost-effectiveness of DC Shunts ensure they remain a cornerstone in the measurement of electrical currents.

The comparison with technologies like Hall sensors underscores a vital point: while innovation continues to provide advanced solutions for current measurement, each technology has its domain of optimal application. DC Shunts, with their direct approach to measuring current, offers a blend of reliability and precision that is hard to match, especially in high-current scenarios.

Moreover, the practical applications of DC Shunts across industries—from industrial control systems and power generation to automotive and aerospace—illustrate their versatility and the critical role they play in maintaining the safety, efficiency, and reliability of electrical systems. Whether

it’s in the development of electric vehicles or the monitoring of power in renewable energy systems, DC Shunts are an integral part of the electrical engineering landscape.

In conclusion, the role and impact of DC Shunts in electrical systems transcend mere current measurement. They are a testament to the principle that sometimes, the simplest solutions are the most effective. As technology evolves and our electrical systems become more sophisticated, the humble DC Shunt remains a pivotal element, anchoring our systems with its proven reliability and uncompromising accuracy. In the dynamic world of electrical engineering, the DC Shunt stands as a silent, yet powerful guardian of integrity and performance, ensuring that our leap towards technological advancement is both grounded and secure.