In the world of electrical engineering, DC shunts play a vital role in accurately measuring current and protecting sensitive components within electrical circuits. But what exactly is a DC shunt, and how does it work? In this article, we will delve into the basic principle of a DC shunt, explore its core functions, compare it to other current measuring devices, and examine its practical applications in various industries.

Understanding the Function of a DC Shunt

A DC shunt is a precision resistor designed to divert a known portion of current in a circuit. It provides a low-resistance path for the current to flow, allowing for accurate current measurement. Unlike other types of shunts, such as AC shunts used in alternating current applications, DC shunts are specifically designed for direct current systems.

The basic principle behind a DC shunt lies in Ohm’s law, which states that the current flowing through a conductor is directly proportional to the voltage across it and inversely proportional to the resistance. By connecting a shunt resistor in parallel with a load, a known portion of the current is diverted through the shunt, creating a voltage drop across the resistor. This voltage drop can then be measured and used to determine the current passing through the circuit.

Key Components and Types of DC Shunts

DC shunts typically consist of a resistive element, which is connected in parallel with the load. There are several types of DC shunts, each with unique characteristics and applications. Let’s explore three common types:

- Wire-Wound Shunts: These shunts are constructed using a high-grade resistive wire wound on a non-conductive core. They are known for their high current-handling capabilities and low-temperature coefficients. Wire-wound shunts are commonly used in heavy-duty industrial systems, automotive applications, and large-scale electrical installations.

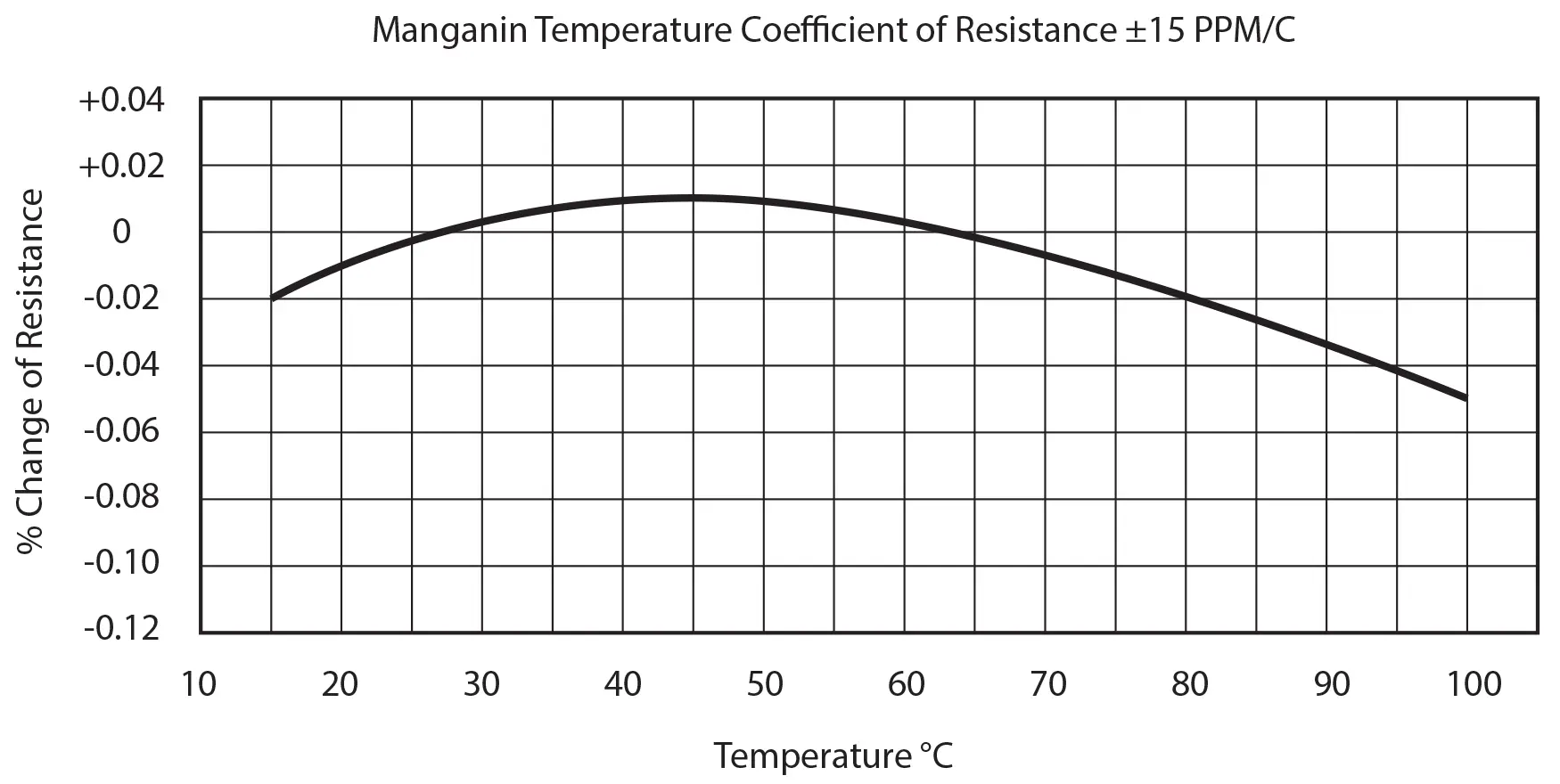

- Manganin Shunts: Manganin shunts are made from an alloy composed of copper, manganese, and nickel. This alloy exhibits low-temperature coefficients and excellent long-term stability, making manganin shunts ideal for precision measurement instruments, laboratory equipment, and applications where high accuracy is paramount.

- Solid-Shank Shunts: These shunts are made using metal bars or plates and are compact in size. They are highly suitable for portable devices and small-scale electrical systems where space is limited.

Comparing DC Shunts with Other Current Measuring Devices

When it comes to measuring current, there are several other devices available besides DC shunts. Let’s compare DC shunts with some of these devices:

- Ammeters: Ammeters are devices specifically designed to measure current. Unlike DC shunts, which divert a portion of the current, ammeters are connected in series with the load and measure the total current flowing through the circuit. Ammeters are commonly used in applications where precise current measurement is required.

- Hall Effect Sensors: Hall effect sensors are semiconductor devices that use the Hall effect to measure current. They are based on the principle that when a current-carrying conductor is placed in a magnetic field, a voltage is generated perpendicular to both the current and the magnetic field. Hall effect sensors offer non-contact current measurement and are often used in automotive and industrial applications.

- Current Transformers: Current transformers, also known as CTs, are devices that use the principle of electromagnetic induction to measure current. They consist of a primary winding through which the current to be measured passes, and a secondary winding connected to a measuring instrument. CTs are commonly used in high-current applications and power distribution systems.

While each of these devices has its own advantages and applications, DC shunts are particularly useful in situations where the current is too large to be measured directly by a panel meter or other instruments. Their high accuracy, cost-effectiveness, and ability to handle high current levels make them a preferred choice in many electrical systems.

Practical Applications of DC Shunts in Various Industries

DC shunts find wide-ranging applications in various industries. Let’s explore some practical uses of DC shunts:

- Power Generation Systems: In power generation systems, DC shunts are used to measure the current flowing through generators, alternators, and other electrical power sources. Accurate current measurement is crucial for monitoring the performance and efficiency of these systems.

- Motor Control and Protection: DC shunts play a vital role in protecting motors and control systems from overloading and damage. By accurately measuring the current flowing through the motor, shunts ensure that the motor operates within its safe operating limits.

- Battery Management Systems: DC shunts are commonly used in battery management systems to measure the current circulating through batteries. This information is essential for monitoring battery health, optimizing charging and discharging processes, and preventing overcharging or over-discharging.

- Renewable Energy Systems: In solar power systems and wind turbines, DC shunts are utilized to measure the current produced by the renewable energy sources. This information is critical for assessing the efficiency of the system, tracking power output, and optimizing energy harvesting.

- Industrial Control Systems: DC shunts are widely used in industrial control systems, such as control panels, motor control centers, and programmable logic controllers (PLCs), to regulate current levels. They ensure that the electrical equipment operates within safe parameters and prevent damage due to excessive current flow.

These are just a few examples of the many applications of DC shunts in various industries. Their versatility and ability to handle high currents make them indispensable components in electrical systems.

Conclusion

DC shunts play a crucial role in accurately measuring current and protecting sensitive components within electrical circuits. By diverting a known portion of current through a precision resistor, DC shunts enable accurate current measurement and ensure the safe operation of electrical systems. Their high accuracy, cost-effectiveness, and versatility make them valuable tools in a wide range of applications, from power generation to industrial control systems. By understanding the basic principle of DC shunts, exploring their types, comparing them to other current measuring devices, and examining their practical applications, engineers and technicians can make informed decisions and ensure the optimal performance of electrical systems.