In electrical systems, accurate current measurement is vital. Beam welded shunt resistors are special components for this. They are rugged and precise. These resistors play a key role in high-current applications. They help ensure efficient

power management. Engineers must understand beam welded shunts well. Their design, working, and uses are important. This knowledge helps optimize electrical systems.

Our guide talks about beam welded shunts. We will learn about their past, how they are made, and how they work. We will also see where they are used, why they are good, and how to pick the right one for your needs. If you work with electronics or want to know more, this article will teach you about beam welded shunts.

Section 1: Understanding Beam Welded Shunts

Definition and Basics

What is a Beam Welded Shunt?

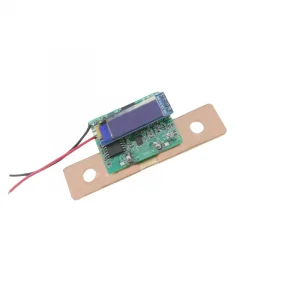

A beam welded shunt resistor is a device used to measure high currents by allowing a precise voltage drop across a known resistance. This voltage drop is then measured and used to calculate the current flow through the circuit. Beam welded shunts utilize electron beam welding to join their components, ensuring high precision and durability.

Brief History and Development

In the past, people needed to measure electric current. This led to making shunt resistors. Shunt resistors got better with new welding methods. Electron beam welding helped make strong welded shunt resistors. We use these high-performing welded shunt resistors now.

Comparison with Other Types of Shunt Resistors

Beam welded shunts have a special way of making them. They use an electron beam welding process. This process makes them very accurate and reliable. Traditional welding does not work as well. Beam welded shunts are great for jobs that need high precision. Traditional shunts may not work as well for those jobs.

Components and Construction

Key Components of Beam Welded Shunts

Beam welded shunts have two main parts. They have a resistive part in the middle. This part has materials like manganin alloys. These alloys are known for low temperature changes in resistance. The resistive part sits between two big copper terminals. All the parts are joined using electron beam welding. This welding helps with low thermal EMF and low measurement inductance.

The Role of Electron Beam Welding in Their Construction

Electron beam welding plays a crucial role in the construction of beam welded shunts. This process involves using a focused beam of electrons to create a high-precision weld. The advantages of electron beam welding include a highly controlled weld environment, minimal heat-affected zone, and the ability to join dissimilar materials with high accuracy.

Advantages of Using Electron Beam Welding

Using electron beam welding in the construction of shunt resistors offers several advantages:

- Precision: The focused electron beam allows for highly accurate welds, ensuring consistent performance.

- Durability: Electron beam welds are robust and can withstand high currents and thermal stresses.

- Low Thermal EMF: The precise construction minimizes thermal electromotive force, which can affect measurement accuracy.

Section 2: How Beam Welded Shunts Work

Principle of Operation

Basic Working Principle

Beam welded shunts operate on the principle of Ohm’s Law (V = IR). By placing the shunt in the path of the current flow, a small voltage drop proportional to the current is generated across the known resistance. This voltage drop is measured and used to calculate the current.

How Electron Beam Welding Enhances Performance

Electron beam welding enhances the performance of shunt resistors by ensuring precise and reliable connections between the resistive element and the terminals. This precision reduces measurement errors and improves the overall stability and accuracy of the shunt resistor.

Electrical Characteristics

Resistance Values

Beam welded shunts are available in a range of resistance values, typically from a few micro-ohms to milliohms. The choice of resistance value depends on the specific application and the current range to be measured.

Temperature Coefficient of Resistance (TCR)

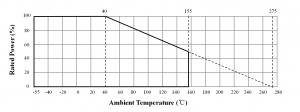

The TCR of a shunt resistor indicates how its resistance changes with temperature. Beam welded shunts are designed to have a low TCR, ensuring stable performance across a wide temperature range.

Thermal EMF and Its Significance

Thermal EMF is the voltage generated due to temperature differences at the junctions of different materials. Beam welded shunts are designed to minimize thermal EMF, which is crucial for maintaining measurement accuracy in varying thermal conditions.

Performance Metrics

Accuracy and Precision

Beam welded shunts are known for their high accuracy and precision, making them suitable for applications requiring exact current measurements. Their construction ensures minimal resistance variation and consistent performance.

Stability and Reliability Under Different Conditions

The robust construction of beam welded shunts ensures stability and reliability even under harsh conditions. They can withstand high currents, thermal cycling, and mechanical stresses without significant performance degradation.

Section 3: Applications of Beam Welded Shunts

Industrial Applications

Energy Metering

In energy metering systems, beam welded shunts provide accurate current measurements essential for monitoring and managing energy consumption. Their precision ensures reliable data for billing and energy management.

Welding Power Supplies

Welding power supplies require precise current control to ensure high-quality welds. Beam welded shunts offer the necessary accuracy and durability to manage the high currents involved in welding processes.

Hybrid Electric Vehicle (HEV) Battery Management

Beam welded shunts are used in HEV battery management systems to monitor the current flow into and out of the battery packs. Accurate current measurement is crucial for optimizing battery performance and longevity.

Consumer Electronics

Examples of Usage in Consumer Devices

Beam welded shunts are also used in various consumer electronics, such as power supplies and chargers, where accurate current measurement is necessary for efficient operation and safety.

Emerging Technologies

Potential Future Applications

As technology advances, the applications of beam welded shunts are expanding. Potential future applications include renewable energy systems, smart grids, and advanced automotive technologies.

Innovations and Trends

Ongoing innovations in materials and manufacturing techniques are likely to enhance the performance and reduce the cost of beam welded shunts, making them more accessible for a wider range of applications.

Section 4: Advantages of Beam Welded Shunts

Performance Benefits

High Accuracy and Low Thermal EMF

Beam welded shunts offer high accuracy and low thermal EMF, ensuring precise current measurements even in challenging conditions.

Robustness and Durability

The electron beam welding process provides robust and durable connections, allowing beam welded shunts to withstand high currents and mechanical stresses.

Manufacturing Advantages

Precision of Electron Beam Welding

Electron beam welding offers unparalleled precision, ensuring consistent performance and minimal variation in shunt resistors.

Cost-Effectiveness and Scalability

Despite their precision, beam welded shunts are cost-effective and can be produced at scale, making them suitable for various applications.

Environmental and Safety Benefits

Low Environmental Impact

The efficient manufacturing process and durable design of beam welded shunts contribute to a low environmental impact, supporting sustainability goals.

Safety in High-Current Applications

Beam welded shunts are designed to handle high currents safely, reducing the risk of overheating and failure in critical applications.

Section 5: Installation and Maintenance

Installation Guidelines

Best Practices for Installing Beam Welded Shunts

Follow best practices for installing beam welded shunts to ensure optimal performance. Proper installation minimizes the risk of measurement errors and component failure.

Common Pitfalls to Avoid

Avoid common pitfalls such as improper mounting, insufficient cooling, and incorrect wiring, which can affect the performance and lifespan of beam welded shunts.

Maintenance Tips

How to Ensure Long-Term Reliability

Regular maintenance and monitoring are essential to ensure the long-term reliability of beam welded shunts. This includes periodic inspections, cleaning, and recalibration if necessary.

Troubleshooting Common Issues

Address common issues such as resistance drift, thermal EMF effects, and mechanical damage promptly to maintain accurate current measurement and system performance.

Appendix

Glossary of Terms Related to Beam Welded Shunts

- Shunt Resistor: A low-resistance resistor used to measure high currents by creating a measurable voltage drop.

- Electron Beam Welding (EBW): A welding process that uses a beam of high-velocity electrons to join materials.

- Thermal Electromotive Force (EMF): The voltage generated due to temperature differences at the junctions of different materials.

- Temperature Coefficient of Resistance (TCR): A measure of how the resistance of a material changes with temperature.

- Busbar: A thick strip of copper or aluminum that conducts electricity within a switchboard, distribution board, substation, or other electrical apparatus.