In today’s interconnected world, where electrical systems power everything from homes to industries, the threat of lightning strikes looms large. A single lightning strike can send a surge of electricity through power lines, potentially causing irreparable damage to sensitive equipment and infrastructure. This is where lightning surge arresters play a crucial role. In this blog, we will delve into the workings of lightning surge arresters, their construction, applications, and why they are indispensable in modern electrical systems.

What is a Lightning Surge Arrester?

A lightning surge arrester, often simply referred to as a surge arrester or lightning arrester, is a device designed to protect electrical equipment from voltage spikes caused by lightning strikes or other transient voltage events. These spikes, also known as surges, can reach thousands of volts and pose a serious threat to electronic devices, appliances, and electrical infrastructure.

How Lightning Surge Arresters Work

The primary function of a surge arrester is to divert excess voltage safely to the ground, thereby protecting the connected electrical equipment. The arrester accomplishes this through a combination of components designed to handle high-energy surges:

1. Metal Oxide Varistors (MOVs)

MOVs are the heart of modern surge arresters. These are semiconductors with a non-linear voltage-current characteristic that allows them to conduct large currents when voltage exceeds a certain threshold. When a surge occurs, the MOVs quickly switch from a high-resistance state to a low-resistance state, providing a path for the surge current to bypass the protected equipment and safely dissipate it to the ground.

2. Gaps and Spark Gaps

Surge arresters also include gaps or spark gaps that help to limit the voltage to a safe level by ionizing and creating a conductive path when the voltage exceeds a certain threshold. These components work in conjunction with the MOVs to ensure comprehensive protection against varying types of surges.

3. Enclosure and Insulation

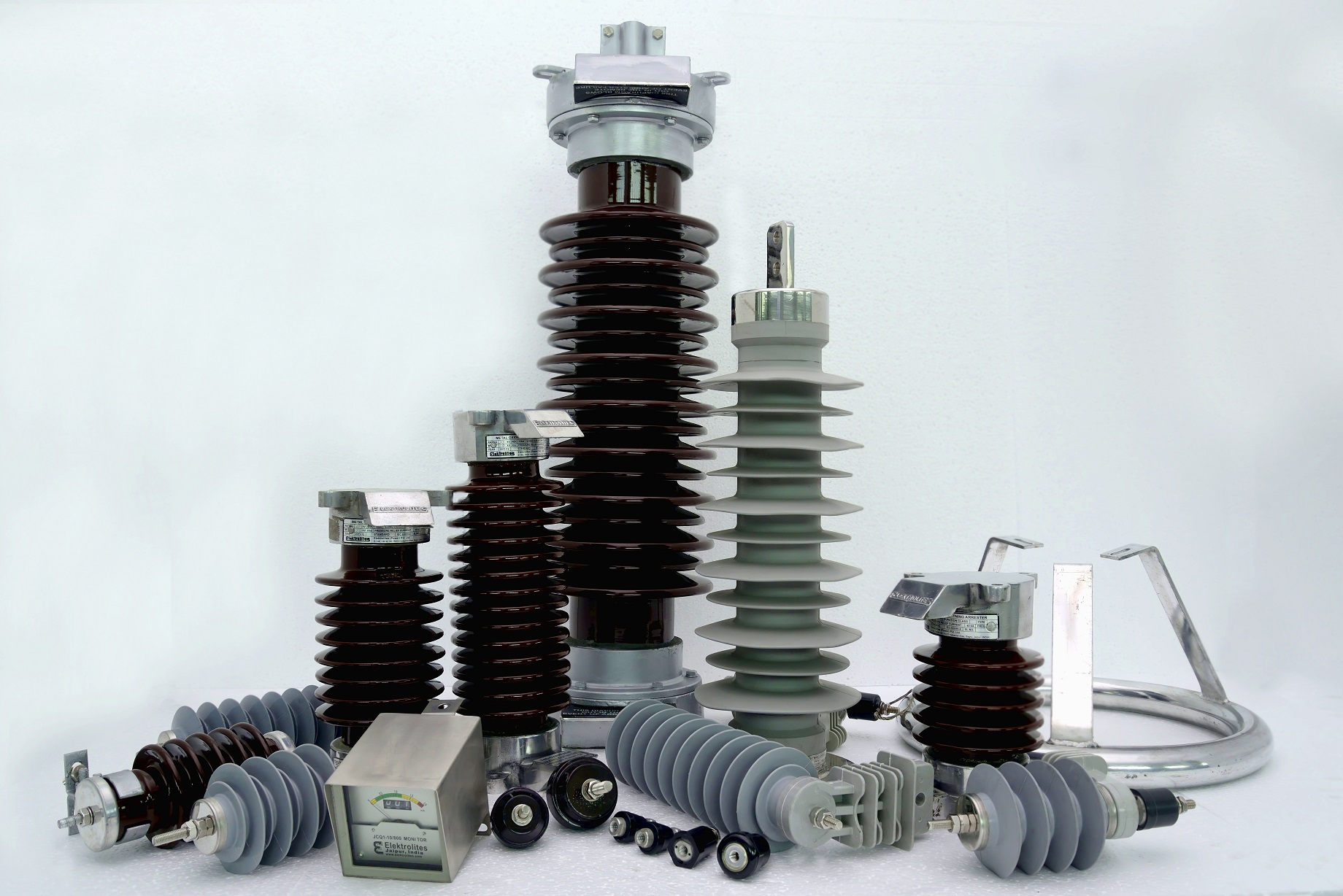

The housing of a surge arrester is typically made of a durable, non-conductive material such as polymer or porcelain. This enclosure not only provides mechanical support but also ensures electrical insulation between the internal components and the environment.

Construction of Lightning Surge Arresters

Lightning surge arresters are constructed with meticulous attention to detail to ensure reliability and performance under extreme conditions:

1. Core Components

- MOVs: High-quality metal oxide varistors are selected based on their voltage ratings and energy absorption capabilities.

- Spark Gaps: Precision-engineered spark gaps that trigger at specific voltage levels to initiate surge diversion.

- Enclosure: Robust housing materials that provide weatherproofing and mechanical stability.

2. Assembly

- Internal Configuration: Components are carefully arranged to maximize efficiency and ensure quick response times to transient surges.

- Sealing: Sealed enclosures prevent moisture ingress, which could compromise the arrester’s performance.

- Testing: Rigorous testing procedures validate each arrester’s ability to withstand and divert high-energy surges effectively.

Applications of Lightning Surge Arresters

The need for surge protection extends across various sectors:

1. Residential

In homes, surge arresters protect appliances, electronics, and electrical systems from lightning-induced surges that could otherwise cause damage or lead to costly repairs.

2. Commercial and Industrial

Industrial facilities rely heavily on electrical equipment that is vulnerable to surges. Surge arresters safeguard machinery, control systems, and sensitive instrumentation from downtime and potential failures.

3. Telecommunications

Telecommunication networks are highly susceptible to lightning strikes due to their extensive cabling and exposed infrastructure. Surge arresters are essential to prevent disruptions in communication services.

4. Power Distribution

Utility companies deploy surge arresters at substations and distribution points to protect transformers, switchgear, and other critical components of the power grid.

Choosing the Right Lightning Surge Arrester

Selecting the appropriate surge arrester depends on several factors:

1. Voltage Rating

Arresters are rated based on the maximum continuous operating voltage they can handle without breakdown. Choosing the correct voltage rating ensures effective protection without compromising safety.

2. Response Time

The response time of a surge arrester determines how quickly it can divert a surge. Lower response times are crucial for protecting sensitive electronics from high-speed transients.

3. Environmental Conditions

Consideration of environmental factors such as temperature extremes, humidity, and exposure to corrosive elements helps in selecting a surge arrester that will perform reliably over its operational life.

Maintenance and Testing of Surge Arresters

Regular maintenance and testing are essential to ensure surge arresters remain effective:

1. Visual Inspections

Inspecting surge arresters for signs of physical damage, corrosion, or degradation helps identify potential issues early.

2. Electrical Testing

Periodic electrical testing, including insulation resistance measurements and surge current testing, verifies the arrester’s functionality and readiness to protect against surges.

3. Replacement

Surge arresters have a finite lifespan and may need replacement after absorbing multiple surges or over an extended period to maintain optimal protection levels.

Conclusion

In conclusion, lightning surge arresters are indispensable components in safeguarding electrical systems from the destructive power of lightning strikes and transient surges. Their robust construction, coupled with advanced technologies such as metal oxide varistors and spark gaps, ensures reliable protection across residential, commercial, industrial, and infrastructure applications. Understanding the principles behind surge protection and choosing the right surge arrester tailored to specific needs are critical steps toward maintaining the integrity and longevity of electrical systems in the face of unpredictable electrical events.