In the realm of electric vehicles (EVs), the integration of DC shunts marks a significant stride toward enhancing efficiency and safety in electrical systems. These specialized resistors, pivotal in the accurate measurement of high currents, are instrumental in the intricate electrical configurations of EVs. The role of DC shunts extends beyond mere current measurement; they are critical in ensuring the precision, quality, and reliability of the electrical systems within these vehicles. Given the rapid advancement and increasing complexity of EV technology, the selection of the right DC shunt becomes paramount. This not only involves considering the shunt’s technical specifications but also its manufacturing quality and the reliability of its source. As electric vehicles continue to evolve and their adoption becomes more widespread, understanding the foundational aspects of DC shunts—from their operational principles to their types and applications—becomes crucial for automotive engineers, EV manufacturers, and enthusiasts alike. This pillar post aims to unveil the transformative impact of DC shunts on electric vehicles, highlighting their indispensable role in the measurement and management of electrical currents, which is essential for the optimal performance and safety of these modern automotive marvels.

Understanding DC Shunts

At the core of DC shunt technology lies a simple yet profoundly effective principle: the precise measurement of electrical currents through the intentional introduction of a known resistance within a circuit. DC shunts are engineered as high-precision resistors, creating a small but measurable voltage drop when placed in series with an electrical load. This voltage drop, directly proportional to the current flowing through the circuit, allows for the accurate determination of current values without significant interference in the circuit’s overall functionality. The choice of material for these resistors is critical, with manganin—a copper, manganese, and nickel alloy—standing out for its exceptionally low temperature coefficient. This property ensures minimal resistance variation with temperature changes, thereby guaranteeing the stability and accuracy of measurements even under fluctuating operating conditions. The manufacturing of DC shunts, therefore, is not merely about assembling components; it is about embedding reliability and precision into the very fabric of electrical systems, particularly in applications as demanding and nuanced as those found in electric vehicles. Understanding these fundamental aspects of DC shunts lays the groundwork for appreciating their pivotal role in the intricate electrical ecosystems of modern EVs, where precision is not just desired but unequivocally required for efficiency, safety, and performance.

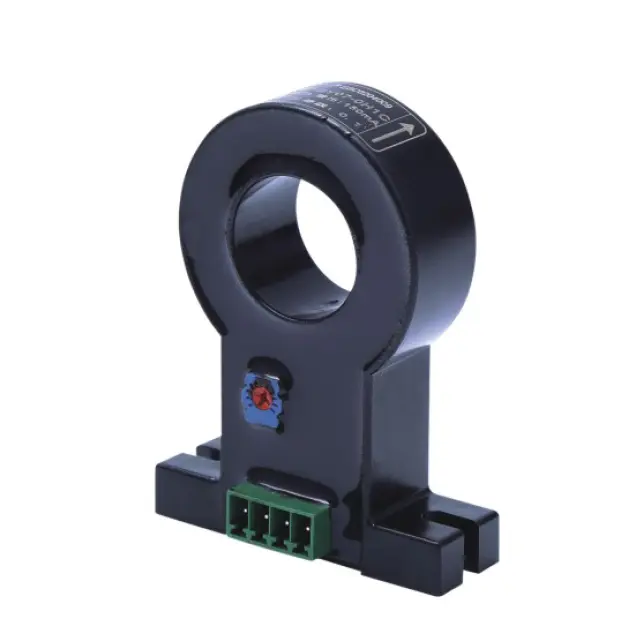

Types of DC Shunts

The diversity in DC shunt types is a testament to the versatile applications and requirements they cater to across various industries, including the burgeoning field of electric vehicles. Among the array of shunts available, three types stand out for their distinct characteristics and suitability for different applications:

Wire-Wound Shunts: Known for their robustness, wire-wound shunts are constructed by winding high-grade resistive wire around a non-conductive core. Their design makes them capable of handling high currents, making them an ideal choice for heavy-duty industrial systems and automotive applications, including the high-demand environments of electric vehicles.

Manganin Shunts: Precision is the hallmark of manganin shunts. Made from an alloy of copper, manganese, and nickel, these shunts boast a low-temperature coefficient and remarkable long-term stability. Their accuracy is paramount in applications requiring meticulous current measurement, such as in the precise electrical systems of EVs where even minor discrepancies can lead to significant impacts on performance and safety.

Solid-Shank Shunts: Compact and efficient, solid-shank shunts are crafted using metal bars or plates and are particularly suited for smaller-scale electrical systems or portable devices. In the context of electric vehicles, these shunts offer flexibility and ease of integration in space-constrained environments, contributing to the overall efficiency and reliability of the vehicle’s electrical system.

Each type of DC shunt brings its unique advantages to the table, catering to the specific needs of electric vehicles, from handling the high currents in powertrain systems to ensuring the precision required in battery management systems. Understanding the nuances of these shunt types enables automotive engineers and EV manufacturers to select the most appropriate shunt for their specific applications, ensuring optimal performance and safety.

Key Specifications and Features

When delving into the realm of DC shunts, particularly within the context of electric vehicles, it’s crucial to consider a set of key specifications and features that dictate their performance and compatibility with various measurement instruments and systems. The accuracy class, often marked at 0.5%, stands as a testament to the precision offered by these components, ensuring that current measurements are both reliable and consistent. This level of accuracy is vital in electric vehicle applications where precise current measurement can significantly impact the vehicle’s efficiency and safety.

Moreover, the versatility of DC shunts is highlighted by the multiple current input options available, allowing for a tailored approach to meet the diverse requirements of different EV systems, from battery management to motor control circuits. The standard 75mV-rated output further facilitates

compatibility, making DC shunts a universal solution for integration with a wide range of measurement and monitoring devices.

The shunts’ overload capacity is another critical factor, with the ability to withstand continuous and short-duration overloads ensuring durability and longevity in the demanding environments of electric vehicles. This feature is particularly important in scenarios where sudden surges in current could potentially compromise the integrity of the electrical system.

Additionally, the temperature range for the operation and storage of DC shunts underscores their robustness, ensuring stable performance across a variety of environmental conditions, which is essential for electric vehicles operating in diverse climatic settings. These key specifications and features collectively ensure that DC shunts not only meet the technical demands of electric vehicle applications but also contribute to the overarching goals of safety, efficiency, and reliability in this rapidly evolving industry.

Installation and Precautions

The installation of DC shunts in electric vehicles (EVs) requires meticulous attention to detail to ensure not only the accuracy of current measurements but also the safety and longevity of the system. Proper mounting is paramount; it facilitates adequate heat dissipation, crucial for maintaining the shunt’s integrity and performance. This is especially important in the compact and

often densely packed electrical compartments of EVs, where efficient heat management can prevent overheating and ensure the shunt’s reliable operation over time.

Equally critical is the minimization of voltage drop across the installation points. Care must be taken to avoid introducing additional resistance at the connection points, which could skew the measurements and potentially compromise the system’s efficiency. In the context of EVs, where every millivolt counts towards optimizing performance and range, ensuring minimal resistance at connection points is non-negotiable.

Moreover, precautions extend beyond the physical installation to the operational parameters of the DC shunts. Not exceeding 80% of the rated current for extended periods is a guideline often emphasized to prevent overstressing the shunt, which could lead to premature failure or inaccurate readings. Given the variable and sometimes unpredictable current flows in EV applications—from regenerative braking to rapid acceleration—adhering to this guideline is crucial for the shunt’s longevity and the overall safety of the vehicle’s electrical system.

These installation and operational precautions are not merely recommendations but essential practices that underpin the effective use of DC shunts in electric vehicles. They ensure that these critical components deliver on their promise of precision and reliability, contributing to the EV’s performance, safety, and user satisfaction.

Advantages of Using DC Shunts

Incorporating DC shunts into electric vehicle (EV) systems brings a myriad of advantages that significantly contribute to the vehicles’ overall performance, safety, and efficiency. The precision and reliability of current measurements provided by DC shunts are fundamental, enabling accurate monitoring and control of the electrical currents flowing through various components of the EV. This precise current measurement is crucial for optimizing battery management, motor control, and energy regeneration processes, directly impacting the vehicle’s range, performance, and longevity.

Cost-effectiveness stands out as a notable advantage of DC shunts. Their relatively low cost, coupled with high accuracy and durability, presents an economically viable solution for current measurement in EVs. This cost-effectiveness is particularly beneficial given the ongoing efforts to make electric vehicles more affordable and accessible to a broader audience.

The high current handling capability of DC shunts aligns perfectly with the demands of electric vehicles, which often operate under high current conditions. This capability ensures that DC shunts can withstand the rigorous

operational requirements of EVs without compromising accuracy or reliability, from rapid acceleration to the charging and discharging cycles of the battery.

The wide application range of DC shunts further underscores their versatility within the EV sector. From power distribution within the vehicle to the integration into charging systems, DC shunts prove to be indispensable in various facets of EV technology. Their simple installation and minimal voltage drop characteristics facilitate seamless integration into EV systems, ensuring that the addition of these measurement components does not adversely affect the vehicle’s electrical performance.

Long-term stability and versatility, coupled with compatibility with existing systems, make DC shunts a preferred choice for engineers and designers in the EV industry. By offering a reliable, accurate, and cost-effective solution for current measurement, DC shunts play a pivotal role in advancing electric vehicle technology, contributing to the development of safer, more efficient, and more reliable EVs for the future.

Applications of DC Shunts in Electric Vehicles

DC shunts find their place in a broad spectrum of applications within electric vehicles (EVs), each contributing to the nuanced and efficient operation of these advanced machines. In the heart of EVs, the battery management system (BMS) relies heavily on accurate current measurement to optimize battery

performance, ensure safety, and extend the battery’s lifespan. DC shunts in BMS applications enable precise monitoring of charge and discharge cycles, crucial for maintaining battery health and maximizing range.

The role of DC shunts extends to the powertrain, where they facilitate the precise control of electric motors. By accurately measuring the current supplied to the motor, DC shunts help optimize the motor’s efficiency and response, contributing to the vehicle’s overall performance and driving experience. This precise current measurement is also pivotal in regenerative braking systems, where it ensures that the maximum amount of kinetic energy is converted back into electrical energy and stored in the battery during braking or deceleration.

Furthermore, DC shunts are instrumental in the EV’s charging system, providing accurate measurements of the current during charging processes. This not only ensures efficient energy transfer but also protects the system from overcurrent conditions, thereby safeguarding both the vehicle and the charging infrastructure. In auxiliary systems such as climate control, infotainment, and lighting, DC shunts contribute to the judicious management of electrical loads, ensuring that the vehicle’s energy is used efficiently without compromising functionality or comfort.

The applications of DC shunts in electric vehicles underscore their versatility and the critical role they play in the safe, efficient, and reliable operation of EVs. From enhancing battery management to optimizing motor control and safeguarding charging processes, DC shunts are integral to the advancement and success of electric vehicle technology, marking them as indispensable components in the EV landscape.

Purchasing DC Shunts in China

Navigating the market for DC shunts in China requires a strategic approach, especially when considering their critical role in electric vehicles (EVs). China, being a hub for electronic components manufacturing, offers a plethora of options for purchasers. However, identifying reputable manufacturers like LEEYD, known for their high-quality products and extensive global clientele, is key to ensuring the reliability and performance of the DC shunts acquired.

When evaluating potential suppliers, it’s imperative to delve into the technical specifications of their products, ensuring they align with the rigorous demands of EV applications. This includes verifying the accuracy class, current handling capabilities, and the environmental robustness of the shunts. Compliance with international standards serves as a benchmark for quality, indicating the manufacturer’s commitment to global best practices and the reliability of their products.

Beyond the specifications, the manufacturer’s support and warranty policies are crucial considerations. Effective technical support can significantly mitigate the risks associated with integrating these components into complex EV

systems, while favorable warranty terms provide an added layer of security, safeguarding the investment and ensuring long-term reliability.

In the dynamic and fast-evolving EV industry, forging partnerships with reputable DC shunt manufacturers in China can offer strategic advantages. It not only ensures access to components that meet the highest standards of quality and performance but also facilitates a collaborative approach to addressing the unique challenges of electric vehicle technology. With the right supplier, purchasers can secure the critical components needed to drive the innovation and success of their EV projects.

Conclusion

In the electric vehicle (EV) industry, where innovation meets practicality, the significance of components like DC shunts cannot be overstated. These seemingly modest devices play a pivotal role in the accurate measurement of electrical currents, a function critical to the safety, efficiency, and performance of EVs. The journey through understanding DC shunts—from their basic principles and types to their applications and purchasing considerations—underscores their indispensability in the EV landscape.

Selecting the right DC shunt involves a careful balance of technical specifications, application requirements, and cost-effectiveness. It’s not merely about choosing a component; it’s about integrating a solution that enhances

the vehicle’s overall functionality and reliability. This process demands thorough research, a deep understanding of the vehicle’s electrical systems, and, importantly, collaboration with reputable manufacturers who can provide not just a product but a partnership.

As the EV sector continues to evolve, pushing the boundaries of automotive technology, the role of components like DC shunts will only grow in importance. Their ability to provide precise current measurements underpins many of the advances in EV technology, from battery management to regenerative braking systems. For manufacturers, engineers, and innovators in the electric vehicle industry, understanding and leveraging the capabilities of DC shunts is a step toward realizing the full potential of their projects and contributing to the sustainable mobility solutions of the future.

In conclusion, DC shunts represent a critical nexus between electrical engineering and automotive innovation. Their selection and integration into electric vehicles encapsulate the meticulous attention to detail and commitment to quality that are hallmarks of the EV industry. As we look to a future where electric vehicles are at the forefront of transportation, the humble DC shunt stands as a testament to the intricate interplay of precision, reliability, and efficiency that will drive this sector forward.